OpenAI's recent 12-day launch event has garnered significant attention from the global tech community, with the most notable highlight being the release of GPT-O3. This AI model, boasting ultra-high computational power, has made remarkable strides in reasoning, generation, and decision-making capabilities, signifying a more significant step for artificial intelligence in the realm of Artificial General Intelligence (AGI). GPT-O3 is not only capable of handling more complex tasks but also adaptable to a broader range of application scenarios, demonstrating an unprecedented level of intelligence.

The rapid iteration of AI technology has not only further increased the demand for ultra-high computational power but also raised the bar for green ICT energy infrastructure equipment providers: providing more effective and reliable Energy Supply and Thermal Management for high-density Data Centers and intelligent computing centers has become key to the success of companies within the industry.

The Rise of High Computational Power: New Challenges for Energy and Thermal Management

In the future, as high computational power AI models like GPT-O3 gradually become commercially available, the operation of Data Centers and intelligent computing centers will face unprecedented pressure. The rapid iteration of AI models, which continuously pushes the limits of computational power devices, poses higher demands on the modular layout of Data Centers and intelligent computing centers—faster deployment of higher computational power devices, and the installation and use of higher power Energy Supply and more precise Thermal Management equipment are required. The necessity of building modular Data Centers is self-evident.

When addressing these challenges, modular Data Centers reveal their unique advantages. Firstly, they offer extreme flexibility and scalability, enabling rapid expansion based on the growing demand for computational power, avoiding the time delays and resource waste that traditional Data Centers may encounter during construction. Secondly, due to the prefabrication and standardization of modular design, the deployment speed is greatly accelerated, allowing companies to respond more quickly to technological changes and shorten the cycle from planning to operation.

Faced with the immense pressure of high-power computational devices on energy demand, modular Data Centers, with their precise energy management systems, can optimize power distribution, improve Energy Efficiency, and effectively reduce energy costs. At the same time, the customized Thermal Management systems of modular Data Centers can be adjusted according to the needs of different regions, ensuring the stable operation of equipment and preventing overheating or malfunctions. More importantly, thanks to their highly standardized design, modular Data Centers can not only reduce initial capital expenditures but also decrease long-term operational costs, and enhance the maintainability and fault tolerance of equipment, preparing for the deployment of higher computational power in the future. For data center builders with small budgets, this is undoubtedly a boon.

Providing Efficient Energy and Thermal Control Solutions for the Era of High Computational Power

To efficiently address these challenges, we offer a range of customized Energy Supply and Thermal Management solutions to ensure that your computational facilities always operate stably and efficiently, enhancing overall business efficiency:

(1) High-Efficiency UPS Systems

To ensure that your equipment always operates stably, we provide online modular UPS and online high-frequency UPS systems that can effectively cope with power fluctuations or failures, avoiding the risk of downtime. Our systems feature delay time calculation capabilities to help you plan power security precisely, ensuring continuous operation of equipment during power outages and maximizing the protection of your critical assets.

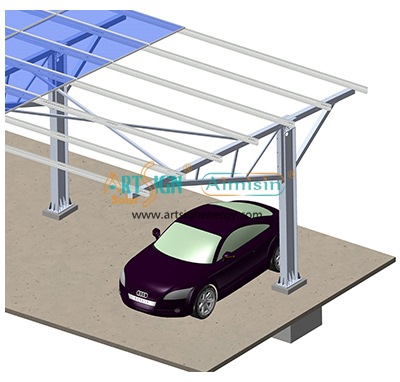

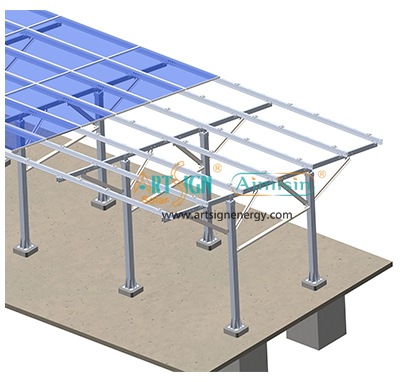

(2) Green Energy Solutions

While reducing energy costs and minimizing environmental footprints, we provide clients with green energy solutions that combine solar and wind energy. Integrated with energy storage systems and smart grids, these solutions can optimize energy management, providing you with more stable energy supply, reducing dependence on traditional energy sources, and supporting your Sustainable Development Goals.

(3) Innovative Thermal Control Technologies

High computational power devices generate a significant amount of heat under high loads, posing a great challenge to Data Center thermal control. Our liquid cooling systems and precision air conditioning solutions can efficiently address this issue, ensuring that equipment remains cool during high-load operations, preventing equipment failures due to overheating, and reducing unnecessary downtime and maintenance costs.

(4) Smart Energy Management System (EMS)

Our Energy Management System (EMS) helps you achieve intelligent energy distribution by monitoring and dynamically scheduling energy loads in real-time. The system can optimize the efficiency of electricity use, reduce operating costs, and improve energy utilization rates, providing you with a more economical and sustainable energy solution that ensures the economic viability of long-term operations.

(5) Environmental Monitoring and Management

By providing temperature and humidity monitoring and fault warning systems, we offer comprehensive environmental monitoring solutions. Monitoring changes in equipment environments in real-time helps you respond quickly to potential failures, preventing equipment damage caused by abnormal temperatures or humidity fluctuations. With data-driven decision-making, you can manage your Data Center more accurately, enhance equipment stability, and reduce failure rates.

Immediate Access to Professional Technical Support to Solve Your High Computational Power Challenges

Find and consult us now, and our professional team will provide you with the following services:

(1)Delay Time Calculation: Precisely evaluate the delay performance of the uninterruptible power supply system to ensure uninterrupted power security and reduce the risk of unexpected downtime.

(2) Air Conditioning Cooling Capacity Calculation: Provide you with thermal control demand analysis to help optimize the cooling system, ensuring that equipment maintains the optimal temperature under high loads.

(3) Power Load Assessment: Analyze the existing power load of the Data Center and predict the power demand after the introduction of high computational power equipment, helping you optimize energy configuration.

(4) Liquid Cooling System Design Suggestions: Provide customized liquid cooling system solutions based on your specific needs, improving cooling efficiency and reducing energy consumption.

With our professional support, you can obtain tailored solutions to ensure stable operation of high computational power tasks, reduce energy waste, and improve overall system efficiency. Whether it's enhancing the efficiency of the UPS system or optimizing the liquid cooling system and thermal control equipment, we can provide professional advice to help you stay ahead in the face of growing computational demands.