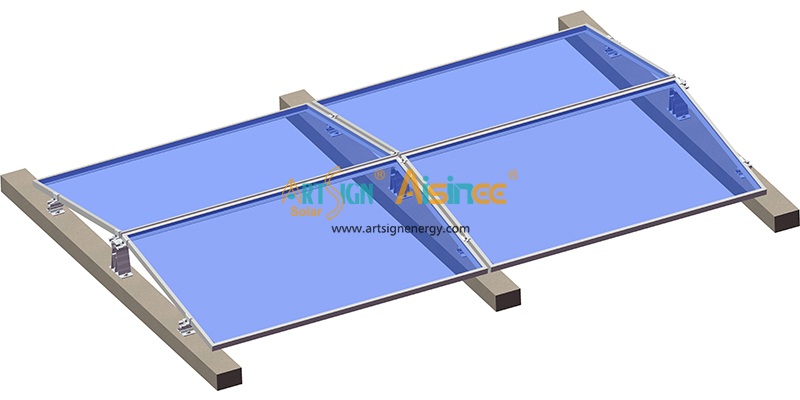

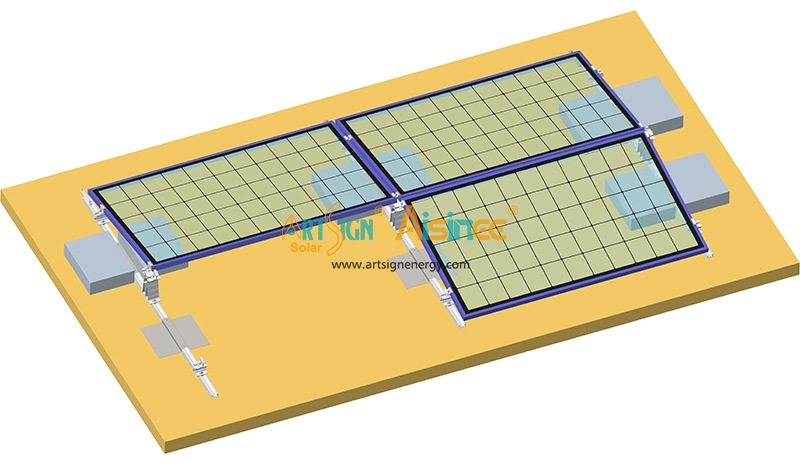

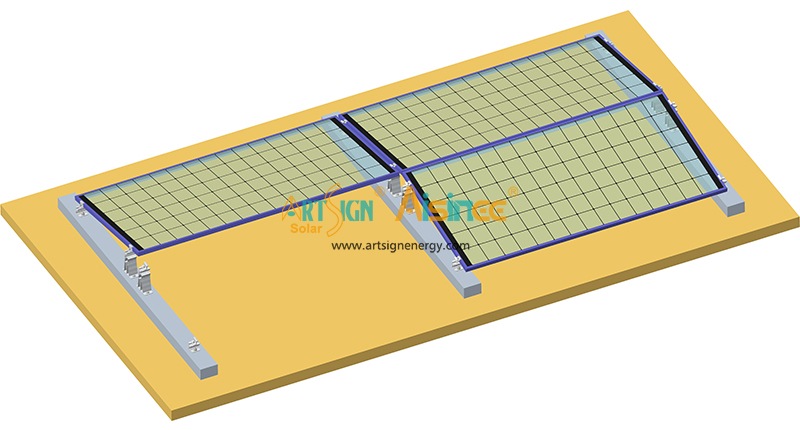

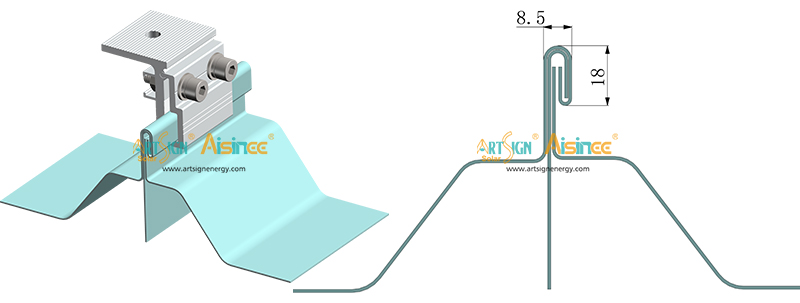

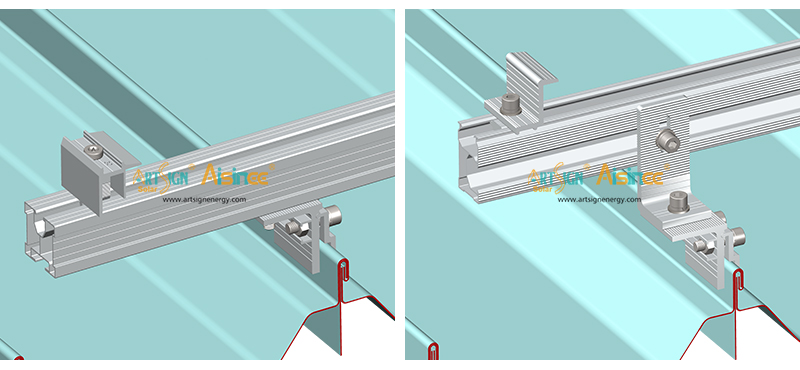

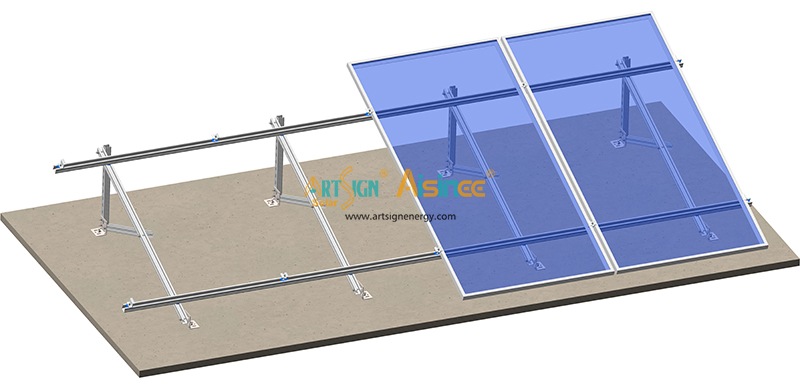

Landpower Steel-Strong Solar Ground Mounting System is applicable to a large array photovoltaic system in open terrain. This system is designed to engineer with a minimum amount of installed footing at greatly reduces labor. As the difference foundation solutions, such as concrete with pre-buried bolt, direct buried and ground screw, the system can be modified to be installed. The special tilt-in module, the clamp and the U-bolt make the installation easy and quick. The customized length can eliminate the weld and cut onsite to keep the high anticorrosive performance, the structure strength and the appearance.

TECHNICAL INFORMATION

Install site:Open ground

Tilt Angle:10~60deg

System Height:<2.5m

Max Wind Speed:<60m/s

Snow Load:<1.4KN/㎡

Standard:AS/NZS 1170 and other international Standard

Material:Aluminum alloy Al6005-T5& Stainless steel 304 & Hot galvanized steel

Anticorrosive:Anodized & Hot galvanized

Color:Natural or Optional

Warranty:Ten years warranty and up twenty years service life

BENEFITS

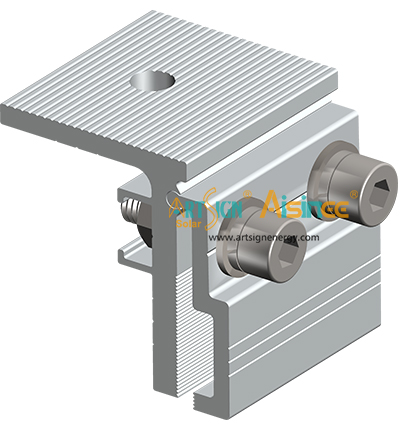

1, Fast Installation

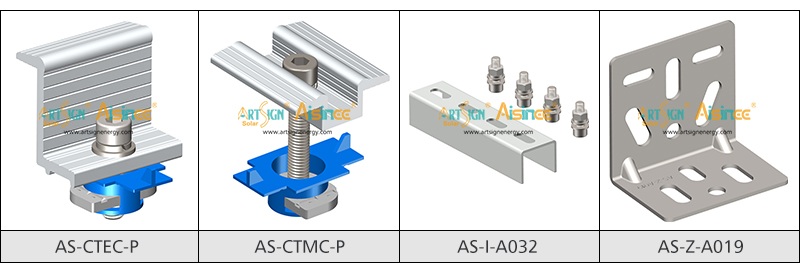

The tilt-in T module can be put into the extruded rail from the any location and can be highly pre-assembled with the clamp and L bracket ensure a fast and easy installation process.

2, Stand up to extreme weather

The PV mounting system is designed to stand up to the extreme weather complied with international structure load standard by the skilled engineer. The main support components also have been test to guarantee. Its structure and load-carrying capacity.

3, Economical

The mounting structure is a cost effective mounting solution. The quantity of components can be required and sold according to project specific calculations. The various components can be kept in stock to shorten time between planning and installation.

4, Long lifespan

All mounting structural components are made of high class stainless steel and anodized aluminum alloy, their high resistance to corrosion and they are designed for twenty-year service life and backed by ten years warranty.