Golf carts are heavy, and they are meant to run for hours and miles at a time. They’re electric vehicles that can reach speeds of approximately 15, sometimes 19, or 20 miles per hour depending on the make, model, and year of the cart. They require electricity or gasoline to run. Usually, people use mains power to charge it by plugging in, and it brings an extra payment for the electricity bill. But have you thought of a solar-powered golf cart?

Can you Charge a Golf Cart with Solar Power?

A solar-powered golf cart is indeed possible. Such vehicles have been in use for several years and are gaining in popularity. They exist, and they function well. Changing the power source to solar doesn’t diminish a golf cart’s speed or performance. In addition to continued performance power, there are reasons why you should consider a solar panel golf cart.

What Golf Carts can be Powered with Solar?

Any golf cart will be powered with solar as long as its battery is solar-rechargeable.

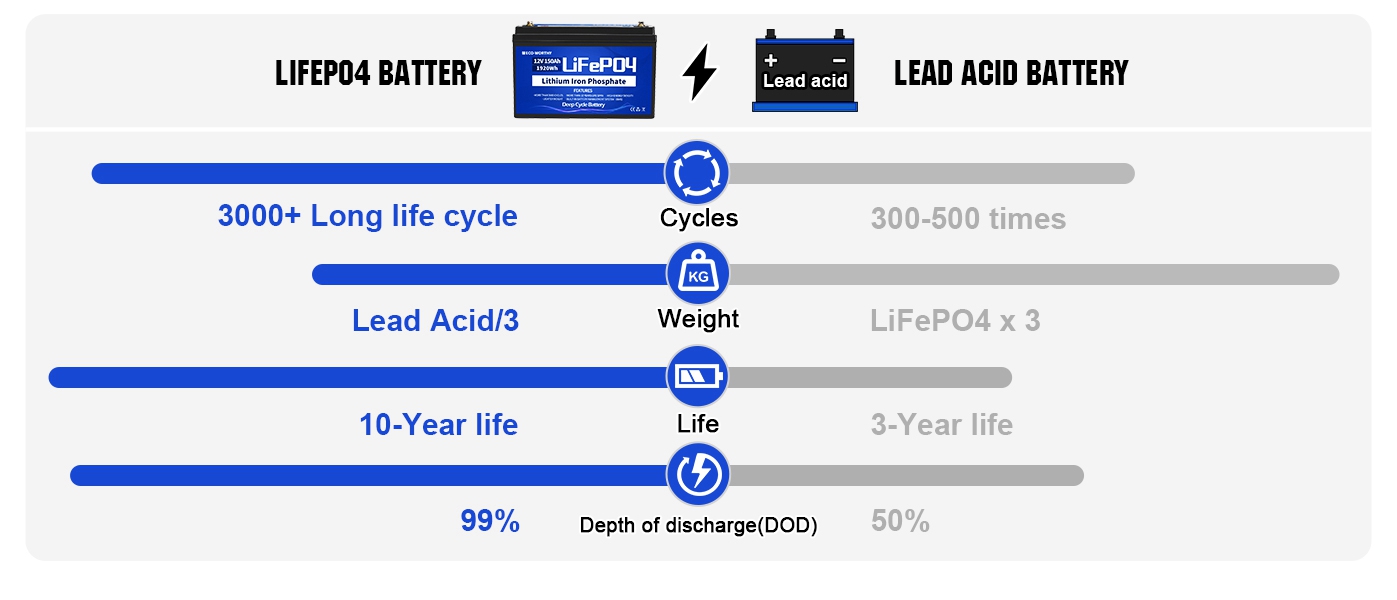

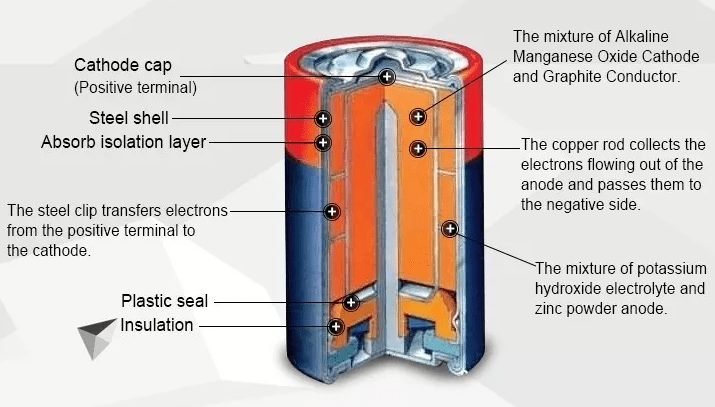

A solar panel can charge most batteries (lead-acid, lithium-ion, and AGM), so yes, almost all golf carts can be powered with solar. And aren’t these the batteries we use in a typical solar power system?

Why Consider a Solar Panel Golf Cart

Benefits of a Solar Power Golf Cart

Performance

Environment

Finance

Performance Benefits

When thinking of building a solar roof on a golf cart, people usually care about the performance of solar-powered golf cart, such as:

How well a golf cart can perform when powered by the sun

Whether a solar panel kit will get enough power to maintain speed

How long does a charge last to charge the battery fully when use solar

Solar panel golf carts have as much power as traditional carts because the batteries stay the same. They aren’t slow, they stop and start with as much vigor as high-performing electric or gas carts.

The range (both driving distance and running time) of a solar-powered cart is normally better than a traditionally powered golf cart. It’s because the batteries still are charged when driving. A solar-charged cart goes up to five miles farther and has 10 percent more driving time per charge than a cart that has to be plugged for a charge.

Using solar power to charge your batteries can avoid low-speed or flameout situations caused by insufficient power while driving, and extends their life significantly. With the sun powering your golf cart, you’d no longer worry about being out on the course too long and having to deal with a dead battery

Likewise, you’d have no more hassles with a normal charger and having to watch to prevent it from overcharging.

Environment Benefits

Solar energy is clean. No carbon dioxide is released into the atmosphere as it is when batteries are plugged into the wall to charge. Similarly, no fossil fuels are consumed as they are in gas-powered golf carts.

Financial Benefits

Of course, you need to prepare a budget if you want to build a solar roof on your present golf cart. But as a long-term valid power, the solar panel usually can work for more than 20 years, consider the electricity bill it saves for you for such a long time, its ROI can be significant.

So generally, adding solar panels to your golf cart is a brilliant idea that’ll allow you to charge it with free solar energy and run it for a long time while reducing maintenance costs significantly.

How Many Solar Panels Do You Need?

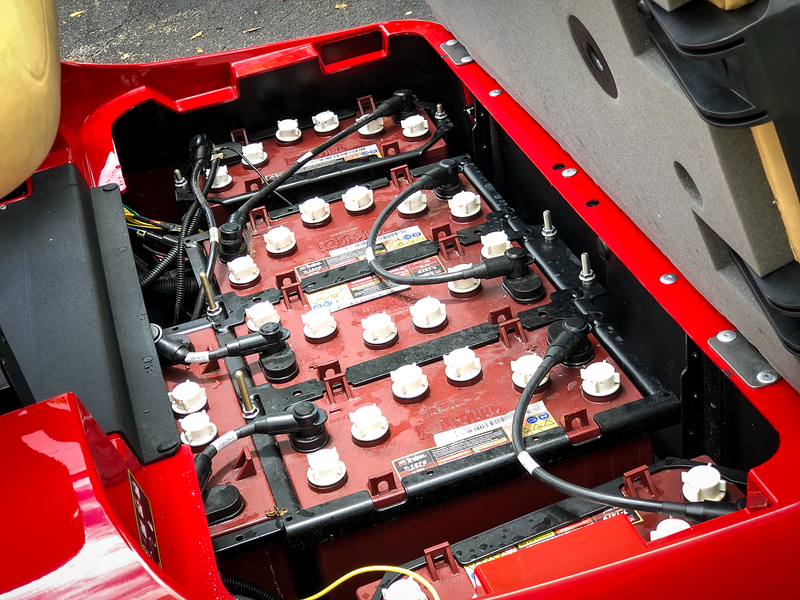

Golf cart’s battery voltage

Proper sizing of the solar panels is crucial for this project. Solar panel voltage should match the battery bank voltage for regular charging. Most golf cart batteries are 36V or 48V, this will help you know the size and number of solar panels you need. For example, the available solar panels are 12V, you’ll need 3 for a 36V and 4 for a 48 V solar golf cart battery.

A higher voltage solar panel may work with any charge controller.

The roof size of your golf cart

It may be possible to size solar panels to fit your club car’s battery, but if the roof doesn’t allow for them, you may need to reconsider.

There are generally two ways to add the panels, depending on how big your cart’s roof is:

Buy an entire solar roof panel to replace your existing plastic roof, or

Buy kits containing solar panels for golf carts to add to the roof you have

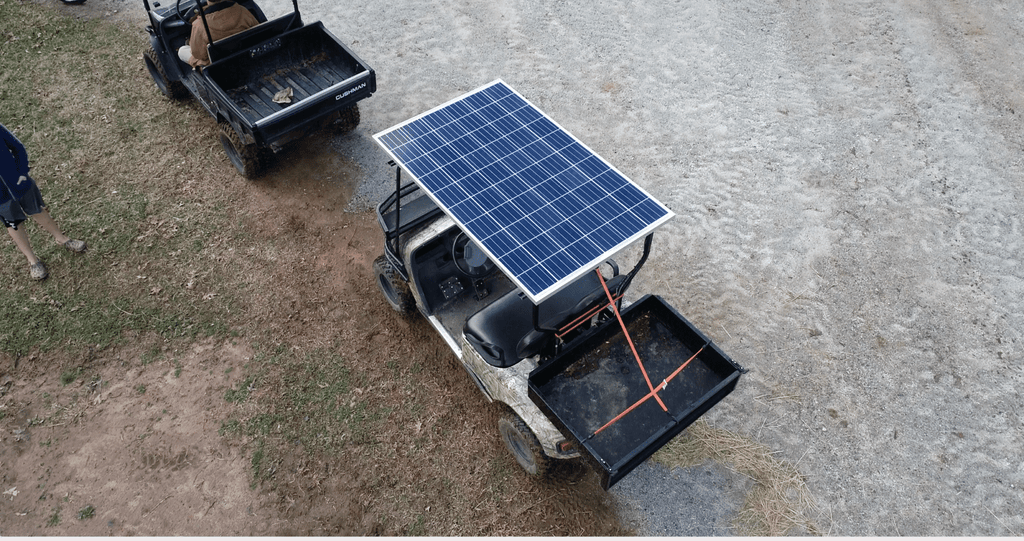

Normally, a 2-seat golf cart’s roof has space for 1 big panel, 100w if you add it on the roof, 300w if you use it to directly replace the original roof.

A 4-seats cart’s roof can handle about 4-5 pieces of 100w solar panels

|

|

How to add a Solar Panel to a Golf Cart

The golf cart solar kit should come with:

The solar panel (s)

Extension cable

Charge controller

Battery connector

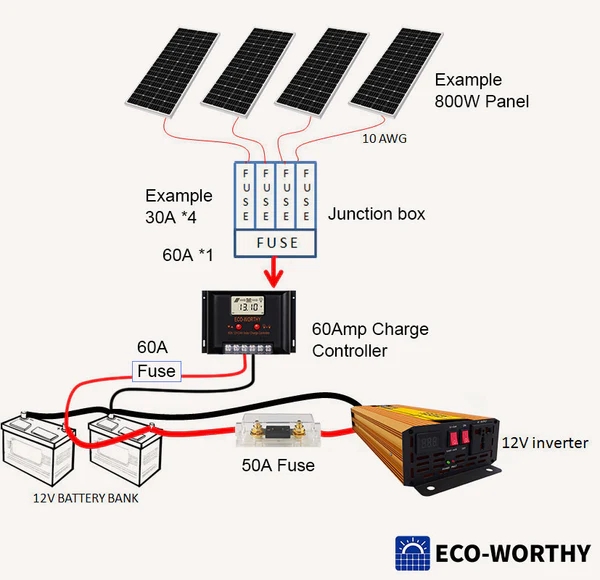

Here are some simple steps to charge your cart with solar:

1. Put the solar panels on the roof of your golf cart, ensuring that it fits perfectly. Also, make sure to use an extension cable to make the panel cable reach the back of the cart.

2. Use mounting brackets or screws to tie the panel

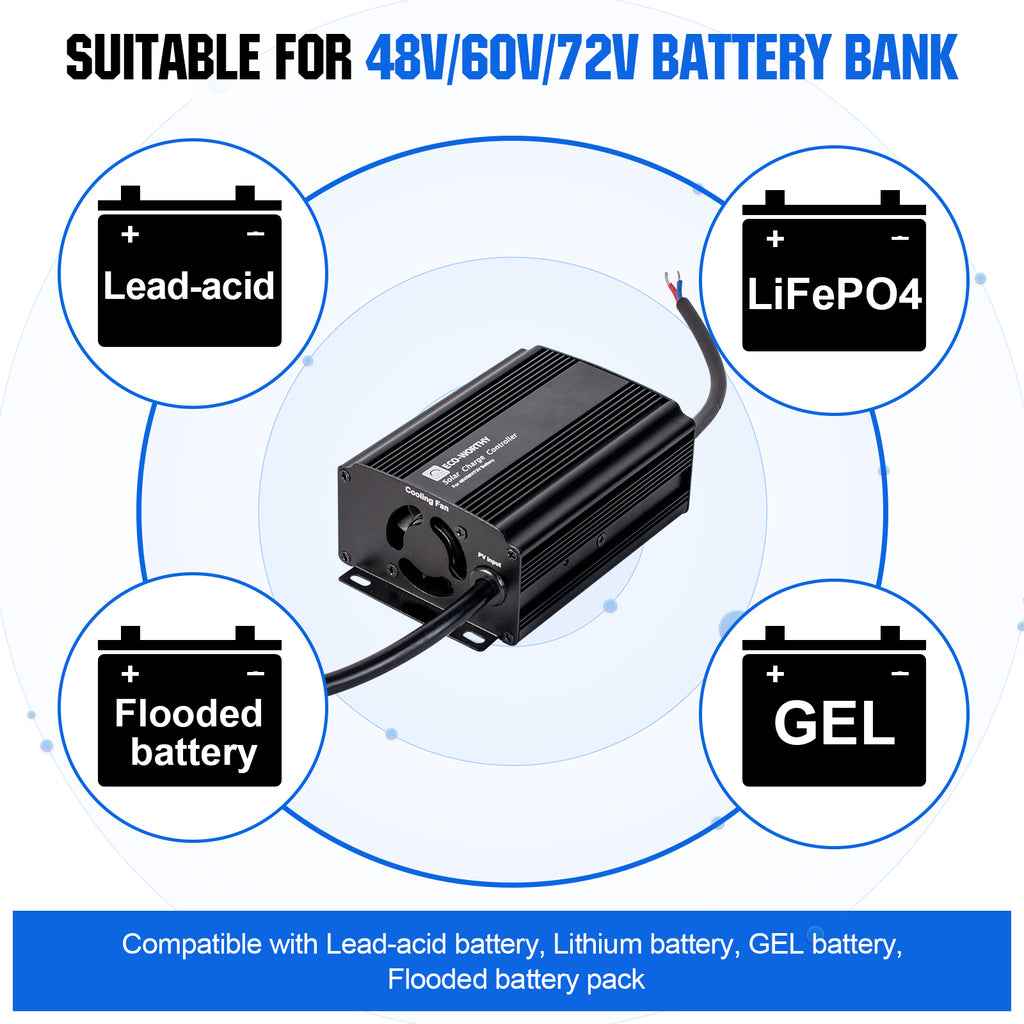

3. Fix the charge controller on the base floor with some tapes

4. Connect the battery bank to the controller’s battery port with a suitable connector

5. Wire the solar panel extension cable to the controller’s PV port to complete the whole installation

Caution: Avoid connecting your golf cart’s battery directly to the solar panel, as doing so may put it at the risk of overcharging and possibly damage.

In addition, we've designed an MPPT step-up boost charge controller for the golf cart solar system, which can convert the 12V current from the solar panel to 48V/60V electricity to charge the 48V/60V golf cart battery bank. Reduce the panel's need and make the connection easier

Golf cart solar panel kit

Except the step-up charge controller, we now provide a whole solar kit solution, which include solar panel(s), this step-up charge controller, brackets for roof installation and necessary wires.

Concerns

Added weight

Solar roofs and weigh more than your golf cart’s original roof. It’s logical to wonder if the extra weight will slow down your cart.

Actually, compared to the total weight of a golf cart (approximately 1100 pounds), the weight of the solar panels (less than 50 pounds) isn’t enough to affect operation.

Hardness

Fortunately, PV panels are very durable and covered by tempered glass, also known as safety glass. It’s able to bear both snow and heavy rain. Unless a ball hits it at an exact right angle, otherwise, nothing will shatter or break it.

Weather condition

Solar panels charge your batteries quickly on a sunny day. While the charging time and productivity won’t be as efficient on a cloudy day as on a sunny one, charging will happen nonetheless, because what the panel needs is just daylight.